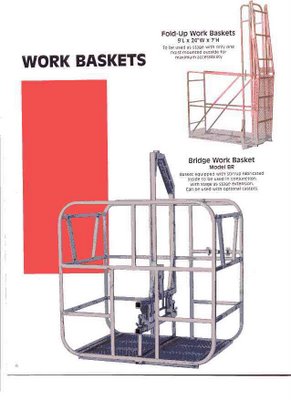

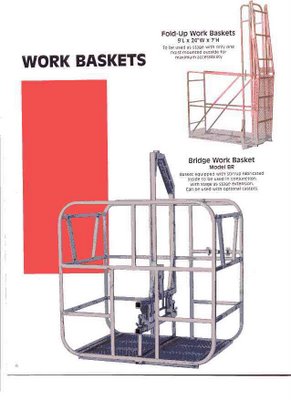

We make our own Workbaskets in a variety of configurations.

The Standard Workbasket, Model STD, is ideal for work on high rise buildings, towers, cranes, tanks and many more applications.

The Bridge Workbasket is custom designed for bridges. The stirrup type yoke configured into this basket allows you to attach swing stages or 'picks'. The yoke swings freely from the basket in the same manner a stirrup does, allowing you to use this basket to join scaffold stages (picks) together with no limit to the overall length. It also operates as a 'stand alone' workbasket' to access tighter spots. The Yoke is removable and can be used as a 'stand alone' stirrup' which joins stages (picks) together either straight or at any angle up to 90 degrees in either direction. This Yoke, when used with stages (picks), can completely surround bridge pylons enabling you to complete work on a pylon in one drop. The Demountable Basket is identical to the Standard Basket but can be disassembled, allowing it to pass thru an 18 inch opening.The Foldup Basket folds to the size of a stepladder for storage and for passing thru small openings. It opens to 9 feet and allows you to work in much the same way as a stage or pick would, but requires only one hoist instead of the two needed by a stage. The overhead outrigger prevents tipping as you move from one side to the other. These Foldup Baskets can be custom manufactured to pass thru an opening as small as 12 inches.

.

.

.

Accessories include Wire Rope, Rigging Hardware, Stirrups, Cornice Hooks, Parapet Clamps, Outrigger Beams and Stands, Counterweights, Tank Top Rollers, Angular Stirrups, Roller Bumpers, Wire Winders, Safety Harnesses and Line, Rope Grabs, Air Fittings, Filters and Lubricators, Buck and Boost Transformers, Extension Cords, Electric Yokes, Protective Covers and much more.

.

. The Bosun Chair is perfect for smaller jobs or inspection applications. It is also great for Hull repair and maintenance.

The Bosun Chair is perfect for smaller jobs or inspection applications. It is also great for Hull repair and maintenance.

.

.

If you are looking for a custom designed product to fit your special application, give us a call. Our Engineers design specialty equipment anytime. Whether it's a remotely operated hoist, a colapsing platform to fit into the neck of a tank, custom bridge trolleys or whatever your needs may be, we do it. And we do it well! Need your air motors repaired or rebuilt? We do it!

.

.

A Comparison of other Hoists to American Climber

There are several differences between the other hoists and those manufactured by American Climber. The Other hoists use one (1) wrap of wire rope around its one drum, a configuration we at American Climber do not approve of. Or they consist of two (2) drums, each having one half (1/2) of a wrap for a total of one wrap of wire rope. Again, we find this unacceptable.

American Climber hoists incorporate a double figure eight loop of wire rope eliminating slippage by increasing the tension and increasing the overall life of the wire rope substantially. This “choking” style actually increases the grip on the wire rope as the lifted weight is increased.

Also, the other double drum hoist uses what are called “Spreader Rollers” to guide the wire rope from one drum to the next. American Climber uses our bowtie cable guides completely enclosing the wire rope as it is transferred from one drum to the other.

Other companies use a couple of spring loaded “pressure rollers” to try to maintain traction. American Climber uses twenty two (22) tension rollers all the way around both drums for positive wire rope tension in any conditions, a major advance in this industry.

Other companies specify that you will have to use a special wire rope available from them whereas the American Climber hoist is designed for a standard 6X31FC wire rope available anywhere.

Finally, the other hoists are advertised as having a drive system consisting of “a pressure disk and a drive disk pressed against each other by preset pressure springs”. The American Climber hoists are a direct drive system through one and one quarter (1 ¼) inch solid steel drive shafts. We believe springs and pressure disks fail, solid steel drive shafts do not.

American Climber Hoists also incorporate an overspeed sensing brake which will stop the unit if the speed should exceed 133% of rated speed, an obstruction safety which will stop the unit’s travel should it encounter an obstruction in it’s path and an overload safety which will not allow the operator to lift a load greater than the rated safe load. We also incorporate a wire rope grab consisting of a wedge style brass shoe which locks the wire rope at the top of the unit in case of a wire rope breakage inside the machine. A positive worm gear in this hoist is completely self-braking which means we do not rely on the electric motor brake to stop hoist travel. If you remove the motor completely, the hoist will not move.

Other companies will charge as much as $1000 or more for the annual inspection and recertification of their equipment. At American Climber, the annual inspection and recertification of the equipment is FREE for as long as you own it. Many people don’t like to spend this kind of money on their equipment every year and may skip it. This could result in unsafe equipment. We offer this service at no charge because we put safety first! American Climber is the only company in the industry with a perfect safety record. We would rather have a perfect safety record than your money.

Add all of this together along with our perfect safety record of 33 plus years and you will see why the American Climber hoist is virtually failsafe.

on model.

on model.